devendra.adsind@gmail.com - GST NO. : 06GEMPD8421J1ZA

- Send Email

| Business Type | Manufacturer, Supplier |

| Finishing | Polished |

| Driven Type | Motor |

| Belt Material | PVC |

| Click to view more | |

Product Details

Machine Material

Mild Steel

Shape

Rectangular

Usage

Moving Goods

Voltage

220V

Country of Origin

India

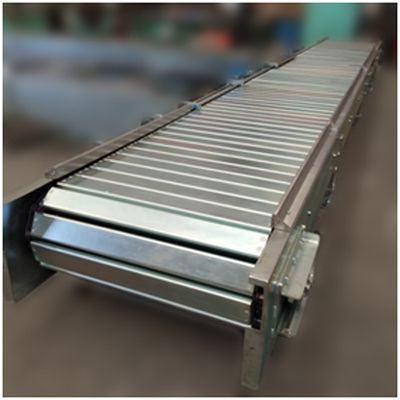

A slat conveyor is a robust material handling system that uses a series of discrete, rigid "slats" attached to a continuous moving chain to transport products. Unlike a belt conveyor which uses a single continuous loop of fabric or rubber, a slat conveyor creates a moving floor made of individual plates (slats).

These systems are the "heavy lifters" of the conveyor world, specifically designed for loads that are too heavy, hot, or abrasive for standard belt conveyors.

Key Features

- Rigid Slat Surface: The carrying surface consists of individual slats made from materials like steel (for heavy loads), stainless steel (for food/hygiene), wood (to prevent damage to soft products), or plastic (for lighter friction).

- Chain-Driven Mechanism: The slats are mounted on one or more strands of heavy-duty roller chain. This chain is driven by sprockets, providing positive drive with no slippage (unlike belt conveyors which rely on friction).

- Fixture Integration: Because the slats are solid and rigid, tooling fixtures or jigs can be bolted directly onto them. This effectively turns the conveyor into a moving workbench, holding parts in a precise orientation for assembly or robotic work.

- Gap Management: The slats are designed to interlock or overlap (often with a "piano hinge" or apron style) to minimize gaps, preventing small parts or debris from falling through the conveyor.

- Flexible Configurations: They can operate horizontally, on inclines (using cleats to stop product roll-back), and can even be installed flush with the floor so workers can safely walk over them.

Advantages

- Extreme Durability: Slat conveyors handle abuse that would destroy a belt. They can transport sharp-edged metal parts, heavy automotive chassis, or massive pallets without tearing or stretching.

- Heat & Corrosion Resistance: Since they do not rely on rubber or fabric belts, they are ideal for high-temperature environments (like drying ovens or foundries) or oily environments where rubber belts would degrade.

- Maintenance Efficiency: If a section of the conveyor is damaged, you only need to replace the individual damaged slats rather than replacing an entire expensive belt.

- Positional Accuracy: The chain drive prevents slipping. This ensures the product is always exactly where the system expects it to be, which is critical for automated lines where robots need to pick up or weld parts on the moving line.

- Stable Work Platform: The rigid surface provides a stable platform for assembly workers. In automotive plants, workers often ride on the slat conveyor along with the vehicle they are assembling.

Common Applications

- Automotive Assembly: Moving vehicle chassis or engines down a production line.

- Bottling & Canning: High-speed movement of bottles (using low-friction plastic slats).

- Heavy Manufacturing: Moving generators, construction equipment, or heavy pallets.

Looking for "Slat Conveyor" ?

Piece