devendra.adsind@gmail.com - GST NO. : 06GEMPD8421J1ZA

- Send Email

| Business Type | Manufacturer, Supplier |

| Material | Rubber, Steel |

| Color | Grey |

| Application | Moving Goods |

| Click to view more | |

Product Details

Certification

CE Certified

Voltage

220V

Country of Origin

India

Finishing

Polished

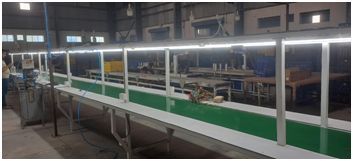

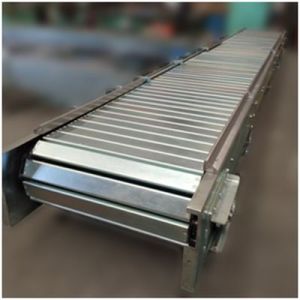

An Assembly Line Belt Conveyor is a continuous material handling system designed to transport components, sub-assemblies, or finished products smoothly through various stages of an assembly process. It provides a controlled and uniform flow of materials, ensuring efficient coordination between workstations. Widely used in manufacturing industries such as automotive, electronics, FMCG, appliances, and engineering, this conveyor improves productivity, consistency, and workflow efficiency while reducing manual handling.

Key Features

- Continuous Belt Operation: Ensures smooth and uninterrupted product flow

- Heavy-Duty Frame Structure: Rigid MS/SS construction for long-lasting performance

- Custom Belt Options: PVC, PU, rubber, or special-purpose belts as per application

- Variable Speed Drive: Speed control to match assembly cycle time

- Modular Design: Easy integration with workstations, fixtures, and automation

- Adjustable Working Height: Ergonomic design for operator comfort

- Low Noise Operation: Suitable for assembly and indoor environments

- Optional Accessories: Side guides, fixtures, lighting, tool rails, sensors, and ESD options

Advantages

- Improves Production Efficiency: Faster and more organized assembly operations

- Consistent Workflow: Uniform movement reduces bottlenecks and downtime

- Reduces Manual Handling: Minimizes product damage and operator fatigue

- Enhances Ergonomics: Comfortable working height improves operator productivity

- Flexible & Scalable: Easy to modify or expand as production needs change

- Low Maintenance: Simple design ensures long service life with minimal upkeep

- Improves Quality Control: Better synchronization between assembly stages

Looking for "Assembly Line Belt Conveyor" ?

Piece