devendra.adsind@gmail.com - GST NO. : 06GEMPD8421J1ZA

- Send Email

| Business Type | Manufacturer, Supplier |

| Shape | Rectangle |

| Warranty | 1 Year |

| Type | Dimensioning, Weighing & Scanning |

| Click to view more | |

Product Details

Material

MS/SS Frame

Usage

Logistics, Courier, E-commerce, Warehousing, Distribution Centers

Advantages

Improves Billing Accuracy,Increases Throughput,Reduces Labor Cost,Real-Time Data Availability,Enhances Sorting Efficiency,Improves Inventory Control,Scalable & Customizable,Low Maintenance & Reliable

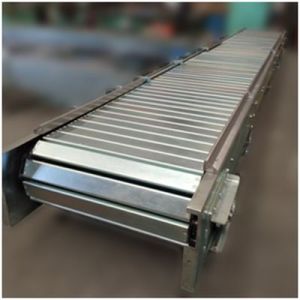

A Dimensioning, Weighing & Scanning (DWS) Conveyor System is an advanced automated solution used to accurately measure the length, width, height, weight, and barcode data of cartons, parcels, and packages while they move on a conveyor. The system integrates dimension sensors, dynamic weighing scales, and barcode scanners into a single conveyor line, enabling real-time data capture without interrupting product flow. It is widely used in logistics, courier, e-commerce, warehousing, and distribution centers for billing accuracy, sorting, tracking, and inventory control.

Key Features

- Automatic Dimension Measurement: Accurately captures L × W × H of parcels in motion

- Dynamic Weighing System: High-precision load cells for real-time weight measurement

- Barcode / QR Code Scanning: High-speed scanners for reliable data capture

- Integrated Conveyor Design: Smooth product flow with stable measurement zone

- High Accuracy Sensors: Ensures consistent and repeatable results

- Data Integration Capability: Connects with WMS, ERP, billing, and sorting systems

- User-Friendly Interface: Touchscreen HMI with real-time display and reports

- Heavy-Duty Construction: Robust MS/SS frame for continuous industrial operation

Advantages

- Improves Billing Accuracy: Eliminates manual errors and revenue leakage

- Increases Throughput: High-speed scanning without stopping parcels

- Reduces Labor Cost: Fully automated measurement and data capture

- Real-Time Data Availability: Instant access to parcel information

- Enhances Sorting Efficiency: Enables faster and accurate parcel routing

- Improves Inventory Control: Accurate data supports better planning and tracking

- Scalable & Customizable: Can be adapted to different parcel sizes and capacities

- Low Maintenance & Reliable: Designed for long-term, continuous operation

Looking for "Dws Conveyor" ?

Piece